3 Things You Probably Didn’t Know about 3D Laser Scanning

Laser scanning is an incredible tool that uses some of the latest technologies and satisfies some important needs. But it isn’t a toy or fad – at least not yet – and it’s not fool-proof. A 3D laser scanner requires some understanding and practice to be used effectively. But for those with the time and money to invest, they are well worth the cost, revolutionizing such industries as design, construction, and engineering. While 3D scanners are becoming more common, here are three things you probably didn’t know.

Laser scanning is an incredible tool that uses some of the latest technologies and satisfies some important needs. But it isn’t a toy or fad – at least not yet – and it’s not fool-proof. A 3D laser scanner requires some understanding and practice to be used effectively. But for those with the time and money to invest, they are well worth the cost, revolutionizing such industries as design, construction, and engineering. While 3D scanners are becoming more common, here are three things you probably didn’t know.

1. How the whole process works

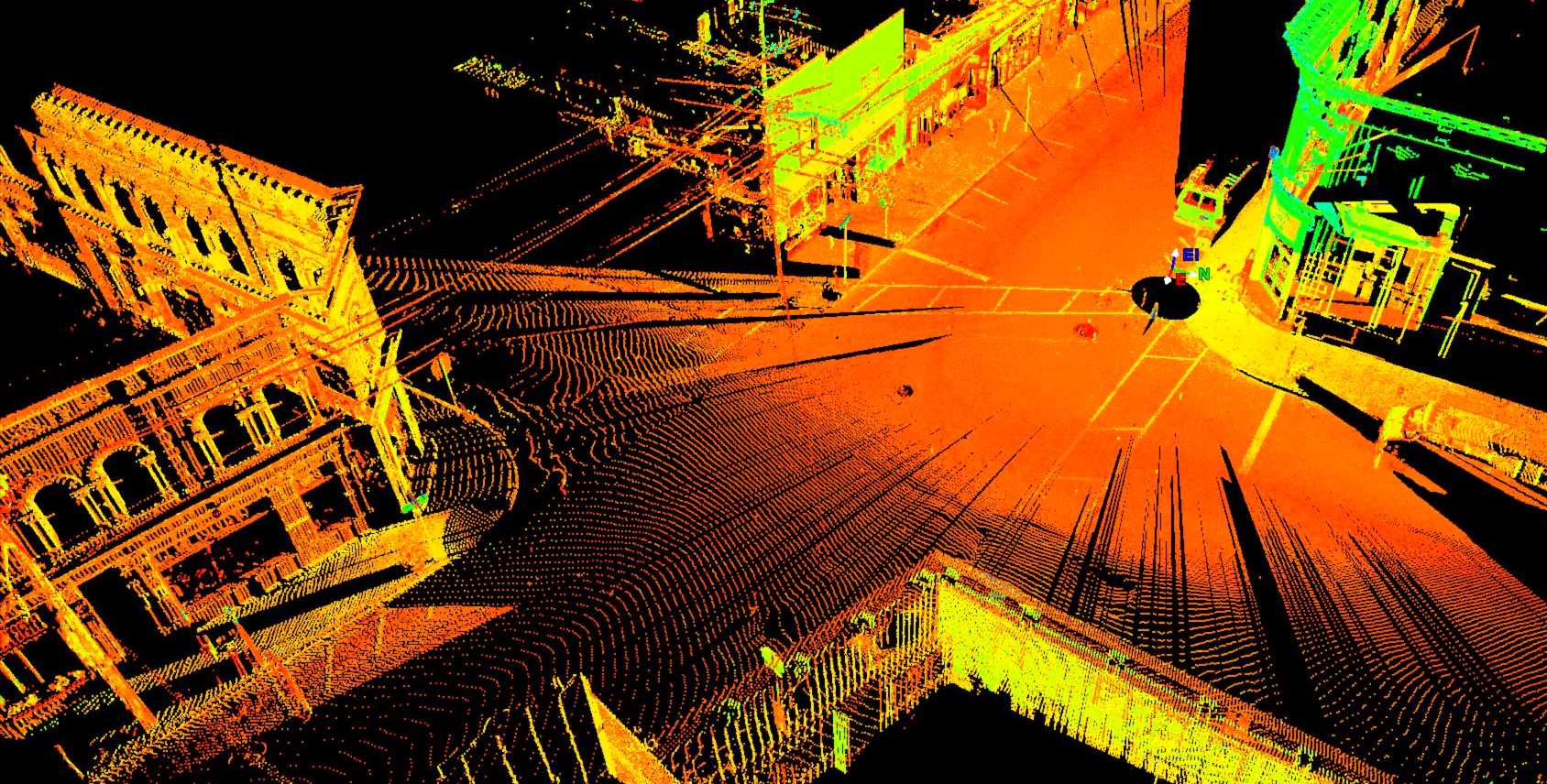

3D laser scanning uses a number of different points (called a point cloud) to map out an object. The reflected/distorted laser beams are measured by sensor to give a very precise indication of the distance to any of these points. There are thousands of laser pulses per second that can effectively map any object from any direction. These cloud-points can be re-assembled by computer into a 3D virtual model. The process can be broken down into:

- Data Acquisition (using of the 3D laser scanner)

- Saving the Useable Data Set (the point cloud)

- Computer Modeling (this depends on the software and the reasons for scanning in the first place)

- Point cloud inspection – if required the scanned object is compared to pre-existing digital blueprints or drawings for accuracy.

- Modeling – the 3D model can then be translated into a 3D CAD (computer aided drafting) model, which allows creating exact plans that can be altered or reproduced into real objects.

2. Handheld scanners work

You may have heard that handheld scanners don’t work well with laser technology because the human hand just can’t keep them still enough to provide accurate measurements. However, that’s changing. Newer handheld scanners can compensate for motion between those nano-second pulses and still capture a point cloud of very detailed objects.

According to TriMet, while fixed scanners are still preferable for long-distance measurements such as surveying or construction sites, handheld scanners are suitable for closer scanning of objects for reproduction in such needs as manufacturing, design, and artwork. Though it may be years before it’s available to consumers, new smartphone designs may incorporate digital scanners for recording 3D images.

3. Scanning and printing

One of the most important uses for these digital 3D designs is with 3D printing. 3D laser scanning is a natural and preferred method for capturing the data needed to reproduce real objects via the additive process of 3D printers, which lay down ink (actually molten plastic and many other materials) exactly as a normal printer does, but in successive layers to create a 3D object. 3D printers are becoming important to manufacturing, design, medical research, and many other fields.

They are also a powerful educational tool. Coupled with 3D laser scanning and 3D CAD, they let students capture and transform objects before re-creating them to explore the whole creative process behind this important technology. This creates a whole new approach to “hands on” learning which allows students to capture any object and make alterations to improve designs and develop innovations. Imagine the possibilities for medical researchers.

The Future

There are bound to legal issues. 3D laser scanners make it possible to capture an exact digital version of almost any object, from a small insect to the latest fighter jet. This could lead to easily stolen designs and a flood of counterfeit products, especially if 3D scanners are incorporated into cell phones, or become affordable and user-friendly enough to empower millions of consumers. Companies and artists will have to take special precautions to insure and protect their intellectual property.

However, 3D scanners also open an incredible potential in vital industries such as healthcare. The ability to easily capture and improve on designs with nothing more than a 3D scanner and printer leads to much faster, cheaper design changes and tests. There are already sites offering hundreds of digital files that can be downloaded and used with 3D printers. As these technologies become more affordable, these possibilities will grow into the millions.

In the meantime, 3D scanners are increasingly vital tools to many industrial and scientific projects, and will help facilitate faster advances.