3 Great Benefits of Owning a Laser Engraver

Laser engraving technology is capable of marking, etching and engraving a wide range of products. Although the initial purchase cost is high, the long-term savings that come with laser engraving technology far outweigh the costs. Laser engraving technology isn’t just used by industrial and manufacturing companies because many businesses use is to enhance products and offer exclusive benefits to customers.

Laser engraving technology is capable of marking, etching and engraving a wide range of products. Although the initial purchase cost is high, the long-term savings that come with laser engraving technology far outweigh the costs. Laser engraving technology isn’t just used by industrial and manufacturing companies because many businesses use is to enhance products and offer exclusive benefits to customers.

Basic Benefits

According to LaserProNA, laser engraving technology can create high precision laser markings and engravings on almost any type of material. This includes metals like gold, silver, brass, platinum, steel, copper, aluminum and titanium. Laser engraving is also used on a wide variety of industrial strength alloys and plastics for medical devices. Laser marking has an excellent reputation for durability and resistance to high temperatures and extreme heats. This is important for medical devices because it ensures that the microscopic etched words will not degrade. The etching process doesn’t use environmentally unfriendly inks, acids and solvents. Instead, laser engraving uses energy to mark biodegradable base metal. All other industry standard marking methods like ink jetting and hand engraving to create traceable words that are prone to fading as time passes. Laser engraving is expected for medical products that come with lifetime traceability requirements.

Industry Benefits

The federal Food and Drug Administration (FDA) has specific requirements for marking medical devices. That is, titanium medical implants must have permanent marks with colored logos, part numbers and serial numbers. The FDA requires that these marks be engraved in machine readable 2D codes. The Bureau of Alcohol, Tobacco and Firearms (ATF) requires that firearms and small arms components have part and serial numbers etched for permanent identification. Automotive manufacturing industry relies on metal vehicle parts with beautiful imprinted graphics. Laser engraving technology is used to mark logos, barcodes, serial codes and certification symbols. It can be used to imprint customized text and alphabetized code. Laser engraving technology is used to marking and cutting light-grade steel sheets and materials. It is used by jewelers for marking precious metals that are heat sensitive.

Production Benefits

- The Production Pros

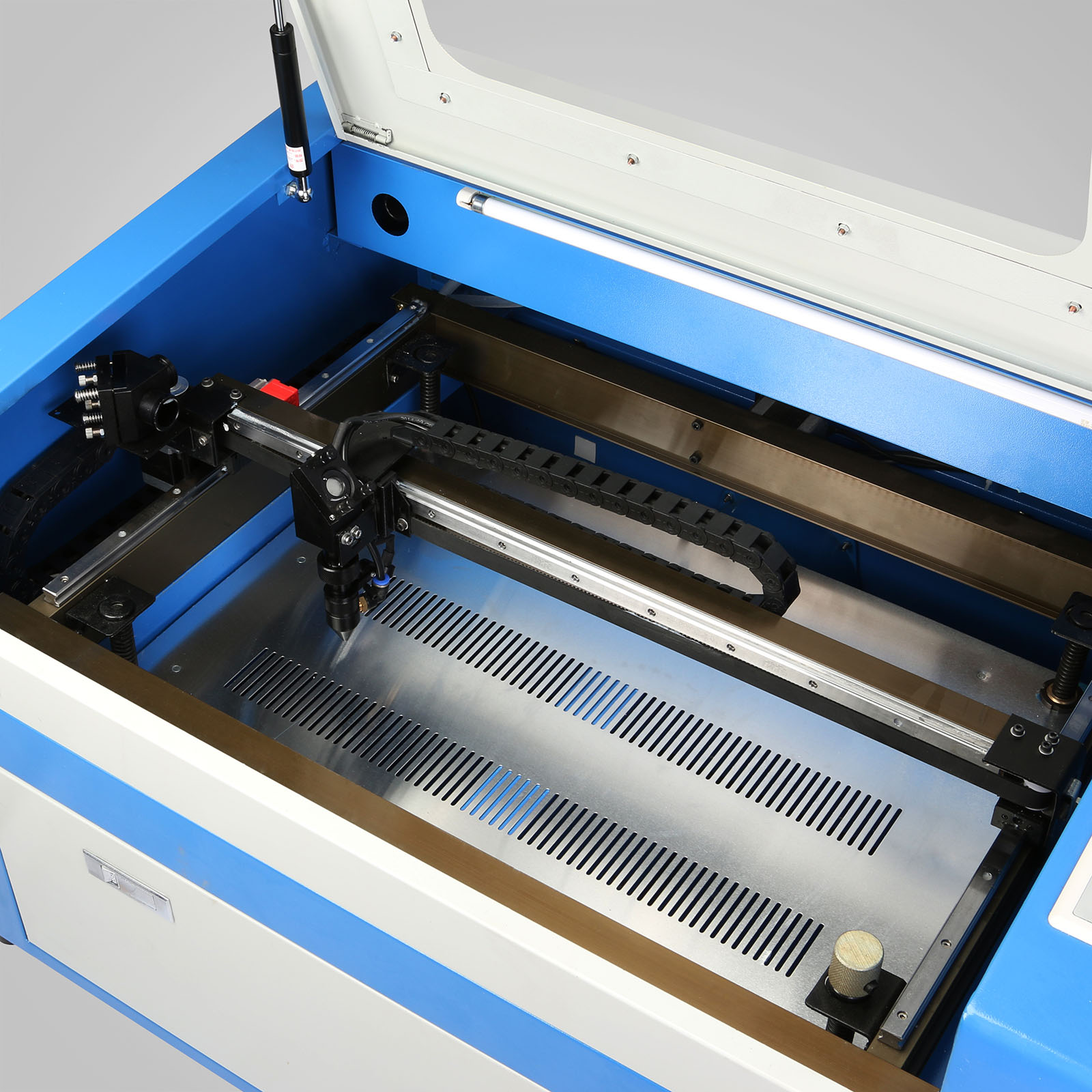

Laser engraving and cutting comes with good benefits for the production of parts. Laser cutters can cut many types of materials and levels of thicknesses. It can be used to cut very narrow widths, which results in more efficient part nesting and operations. Laser cutting offers both customized solutions and programmable settings for accurate, repeat work orders. This reduces the time wasted with repeat machine set up and it saves time when quickly switching production flows for daily client or market demands. Laser engraving, unlike toxic chemicals, do not come with health concerns and excessive material waste. Laser engraving equipment, when operated by an experienced professional, will produce eye-catching products that add value and beauty to the product.

- The Production Cons

There are certain disadvantages of laser engraving and cutting machines that must be properly managed. These machines consume high levels of energy, so their usage must be carefully planned. Poorly adjusted settings may cause product burning or inaccurate markings. Laser engraving technology is considerably more expensive than similar industrial processes like plasma and water-jet cutting. The rate of production on a laser engraving machine depends on the material being used. Some laser engraving machines use high wattage lasers to maintain fast cutting speeds for thicker materials. However, this does consume more energy. Some laser engraving machines will not be capable of cutting reflective metals like brass and copper.

Overall, laser engraving tools and equipment are environmentally friendly ways to produce permanent marks on a wide variety of materials. The non-contact engraving method ensures that there are no tools to wear down or break. Laser marking systems are ruggedly reliable, so they are cost efficient production solutions.